LIST OF SERVICES WE OFFER

- Production machining of die cast aluminum and iron castings and forgings

- Automated Leak testing

- Automated Assembly

- Powder Coating

- Shot Blasting

TECHNOLOGY

We continuously update our technologies employed, so the customer always has the most cost-effective quality product on-time! Some examples of key technologies are as below:

In-House Engineering – Custom Fixture & Tooling Design using advanced CAD systems

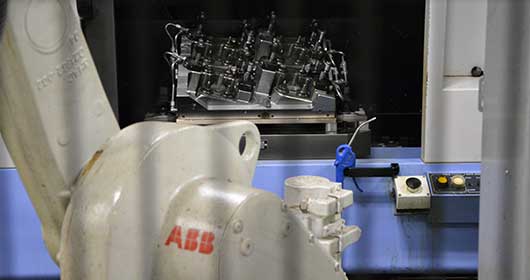

Robotics employed for Machine Tending operations & Material Handling

Custom designed Automated Assembly systems employed for operations such as:

- Fastener Installation – with Torque/Position Monitoring.

- Pin Insertion – with Force/Position Monitoring.

- All operations with built-in Sensors for Poka Yoke ensuring 100% quality to the customer.

Real-time process data collection systems such as:

- Production Data monitoring.

- Quality Data – Measurement, Process variables (Force, Torque, Position, etc).

- Automation Event based notices to responsible team member ie Production/Quality.

Latest MRP system (Industrios) employed to run all operations from order entry, planning, production, inventory, shipment to ensure accuracy and efficiency

PROCESS

We offer a complete end to end solutions for customer requirements. All of the processes below are employed to give our customers a seamless finished product.

• Production CNC Machining – 4 & 5 Axis, HMC, VMC, Turning

• Powder Coating – 2 Continuous Lines

• Shot Blasting – Continuous Line

• Automated Leak Testing

• Automated Dynamic Balancing

• Automated Assembly

• Supply Chain Development/Management Domestic/Offshore

• Logistics/Inventory Management

• Secondary Process – Validated supply base in Heat Treatment, Grinding, Impregnation, Broaching

QUALITY

B.S.B. prides itself providing the highest Quality product by building quality into the process. We are ISO-9001-2015 Certified and comply with AIAG automotive standards:

• ISO 9001-2015 Certified

• Automotive AIAG standards – PPAP, APQP, FMEA, CPLAN

• CMM with 3D Capability

• Special purchase Gages for dedicated data collection and SPC

• Traceability from incoming product to shipment

• Cleanliness Testing laboratory

• Hardness, Surface, Optical, Metrology equipment in house